High quality lathes and milling machines

IPA can, together with partners in Malaysia, supply high quality lathes and milling machines at competitive prices.

IPA International: supplier of high quality lathes and milling machines

IPA can, together with partners in Malaysia, supply high quality lathes and milling machines at competitive prices. If desired, a certificate can also be supplied.

Surface treatments or laser engraving are both possible.

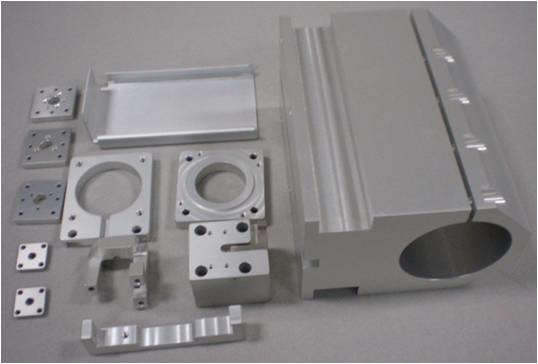

Please take into account that the fabricated materials must be transported to The Netherlands. This takes time and money. Therefore it is particularly interesting for labor intensive, complex parts and series products. In this case the transportation costs are relatively less important. This production method results in a competitive price for your parts or complete machines. This is crucial for landing orders in the near future.

Production is done in Malaysia, in a well-equipped factory in a modern country.

If you have any questions, we will be happy to answer them.

We hope to hear from you. Try us out!

Machine Shop Machines

Machines | Capacity (mm) | Capability (+/-mm) | Quantity |

CNC Milling | 3000 x 1700 | 0.010 to 0.020 | 1 |

CNC Milling | 1200 x 600 | 0.005 to 0.010 | 1 |

CNC Milling | 1000 x 500 | 0.005 to 0.010 | 28 |

CNC Milling | 860 x 550 | 0.005 to 0.010 | 1 |

CNC Milling | 550 x 400 | 0.005 to 0.010 | 1 |

Milling | 300 x 750 | 0.020 to 0.050 | 28 |

CNC Lathe | Dia 200 x 300 | 0.010 to 0.020 | 5 |

Lathe | X=1000, Y=430, Z=NA | 0.010 to 0.020 | 4 |

CNC EDM | X=305, Y=205, Z=250 | 0.005 to 0.010 | 1 |

EDM | 300 x 250 | 0.0150 | 2 |

Super Drill | 250 x 300 | 0.0200 | 1 |

Grinding | 1000 x 500 | 0.005 to 0.010 | 1 |

Grinding | 360 x 200 | 0.002 to 0.010 | 6 |

Wire Cut | X=350, Y=250, Z=150 | 0.002 to 0.005 | 2 |

Laser Cutting Machine | 6000 x 2000 | Up to 6 mm thk | 5 |

Turret Punch | 4000 x 1500 | Up to 1.5 mm thk | 8 |

In-house QC Equipment

Description Manufacturer / Brand Accuracy (+/-mm) Quantity Probe, Laser and Video Vision MAHR MS442 0.003 1 unit Auto CMM (1 meter work table) Brown & Sharpe 0.002 1 unit Co-ordinate Measuring Machine Aberlink 0.003 2 units Video Inspection Machine ST Industries 0.010 1 unit Profile Projector ST Industries 0.012 3 units Digital Linear Height MAHR CX1 0.003 3 units Digital Height Master Mitutoyo/ Trimos 0.002 5 units Hardness Tester AFRI N/A 1 unit Surfaces Roughness Tester Mitutoyo N/A 1 unit Dial Test Indicator TESA 0.002 3 units Bore Gauge Set TESA 0.006 8 sets Depth Micrometer Mitutoyo 0.002 5 units Grinding Mitutoyo 0.015 2 units Wire Cut Mitutoyo 0.020 36 units Laser Cutting Machine Mitutoyo 0.003 19 units Microscope Olympus N/A 3 units Pin Gauge Set TC 0.003 5 sets Precision L Square Ultra 0.080 1 unit Ring Gauge Set TESA 0.002 4 sets Tool Maker Microscope Aseania N/A 1 unit

Surface Treatment

- EN (Electroless Nickel Plating)

- Anodize (Black,Natural,Blue & Gold Colour)

- Hard Anodize (Back & Natural Colour)

- Flash Chrome

- Zinc Plating (Rainbow and Blue Colour)

- Hard Chrome

- Passivate

- Electro Polish (Deeping with Chemical & Manual Polish)

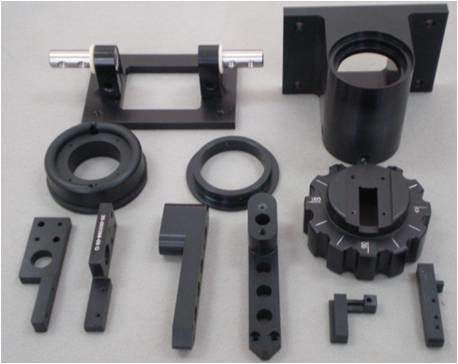

- Black Oxide (Blackening)

- Nituff Coat (Teflon Coating )

- Titanium Coating (TiN, TiCN & CrN)

- Nitriding

- Powder Coating

Electroless Nickel Plating

Clear Anodize

Black Anodize

Special Materials

Glass Ceramic (Marco)

Carbide

ESD Safe

- Semitron 225

- Semitron 410C

- Semitron 420

- Pomalux SD

SST 17-4 PH Pre-Harden

Ceramic Zirconium – EDS Safe

Titanium

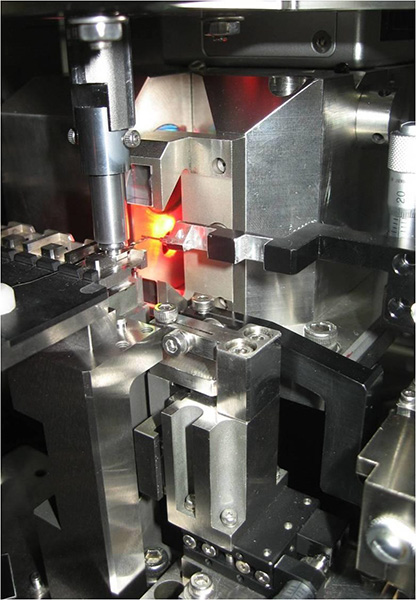

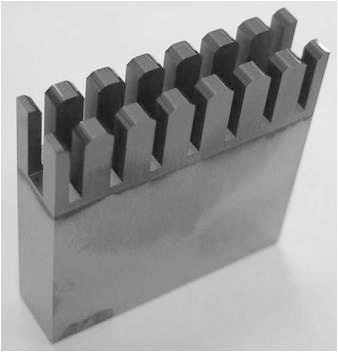

Jigs, Fixtures and Precision Parts

Do you like what you see?

Maybe our creative solutions can be part of your production process.

For more information call:

Gert-Jan Hollestelle

+31 (0)226-335010 (Dutch, German, English)